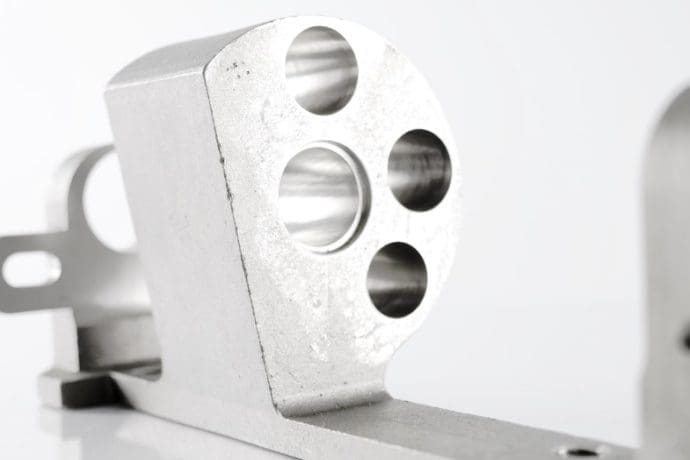

17-4 PH Stainless Steel For Investment Castings

17-4 PH stainless steel, also known as SAE Type 630 steel and UNS S17400 steel, is a precipitation-hardened variety of stainless steel that is known for its hardness, durability, corrosion resistance, high tensile and yield mechanical properties and elongation. Barron Industries specializes in 17-4 PH stainless steel, and provides a wide array of services. Read on to learn more about this type of stainless steel, or call us today to learn more about our services.

17-4 PH Stainless Steel Hardness Properties

Precipitation hardening creates a martensitic structure where small grains prevent movement—this makes 17-4 PH extremely hard, very strong, and magnetic. 17-4 stainless steel also has exceptional corrosion resistance due to its high levels of chromium.

17-4 is used in many oil/gas, defense, marine, and aerospace applications. Its high strength makes it ideal for applications where weight is a concern.

Mechanical Properties

| Stainless Steel | Condition | Tensile Strength (PSI) | Yield Strength (PSI) | % Elongation | Hardness Range or Max |

| 17-4 PH | Age-Hardened (H1350M) | 115,000 to 180,000 | 140,000 to 160,000 | 6 to 20 | 26 to 40 Rc |

Composition

| Chromium (17.5% maximum) | Manganese (1% maximum) | Phosphorous (0.04% maximum) | Sulfur (0.03% maximum) | Silicon (1% maximum) | Nickel (5% maximum) | Copper (5% maximum) |

How We Harden Stainless Steel

Barron Industries achieves varying hardness of 17-4 PH stainless steel using a method called precipitation hardening. This treatment involves heating the stainless steel castings up to 900-1350 degrees Fahrenheit for several hours following its high temperature homogenization or solution heat treat cycle and allowing it to cool to room temperature. This process produces “precipitates” in the metal matrix which stabilizes the steel’s crystalline structure.

The time in which the metal is kept at an elevated temperature is called “aging.” It is crucial that the metal ages for a specific amount of time dependent on the desired hardness and mechanical properties desired.

Equating Hardness into Mechanical Properties

Steel hardness is measured by indentation. Softer metals deform more than hard materials under the same load. This “deformability” correlates with strength: a stronger metal deforms less under load.

Strength is measured with two values, ultimate tensile strength (UTS), the load at which the metal fractures, and yield strength, the load at which the structure begins to stretch. The extent to which it stretches before fracturing is the elongation (technically, measured as percentage strain to fracture.)

Hard metals have a structure that resists deformation, resulting in high values for both UTS and yield strength and low elongation. High hardness and very low elongation indicate a brittle material (consider glass or ceramics, for example.) Conversely, a soft metal like copper has a low UTS but will stretch a long way before breaking.

Precipitation hardening modifies the structure in a way that increases resistance to deformation. In the case of 17-4 PH stainless, the aging component of the heat treatment process determines the size of grains in the structure, with smaller grains increasing resistance to deformation.

Have any Questions?

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.